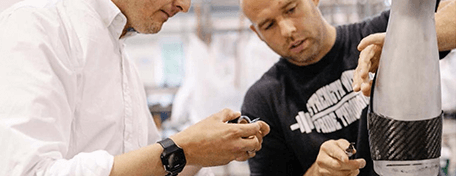

Dynamic manufacturing provides a way to be responsive to the demands of the market and can help to create and accelerate production development. In this programme of research, Lab4Living researchers investigated new ways to design and produce carbon fibre ankle foot orthoses (AFOs).

Funded by Trulife.

Partners:

Trulife

Project Team:

Design Lead – Nick Dulake

The enquiry gathered and analysed published anthropometric data. This was used to create the master CAD design file. The model was parametric, meaning that key dimensions could be changed whilst maintaining dynamic relationships. As a consequence, the master file could be used to create distinct new products that varied in scale or proportion. This meant that the foot orthosis could be customised to an individual. Prototypes were used in development testing with users.

The new system has been the catalyst for a leaner production process within Trulife’s factory in Sheffield, UK. At the end of the project, the new system was capable of producing over 270% of the output when compared to previous techniques whilst achieving higher quality and better consistency of product.

to top

to top